Smart TCA Sensor

Study

Smart TCA Sensor for Process Control in the Cork Industry.

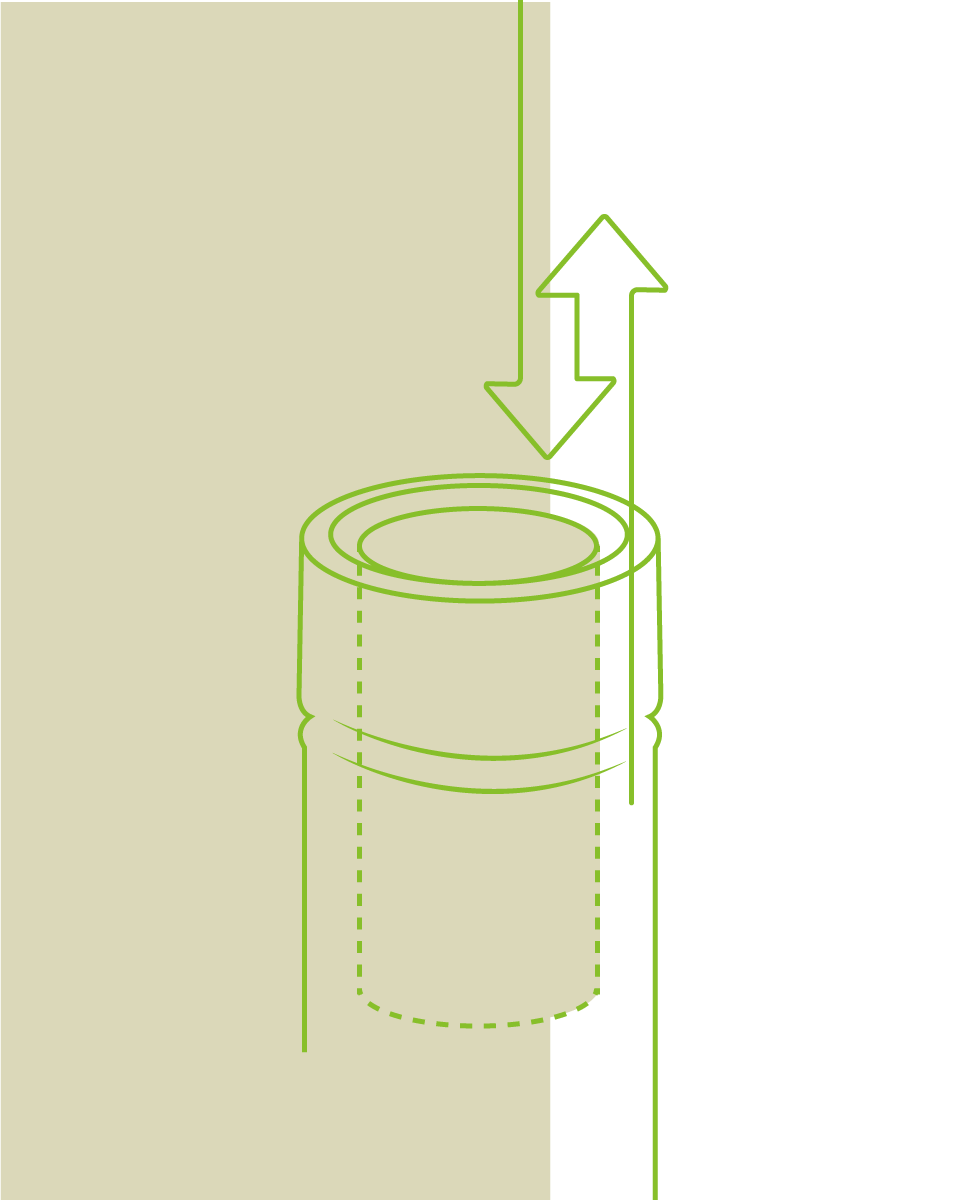

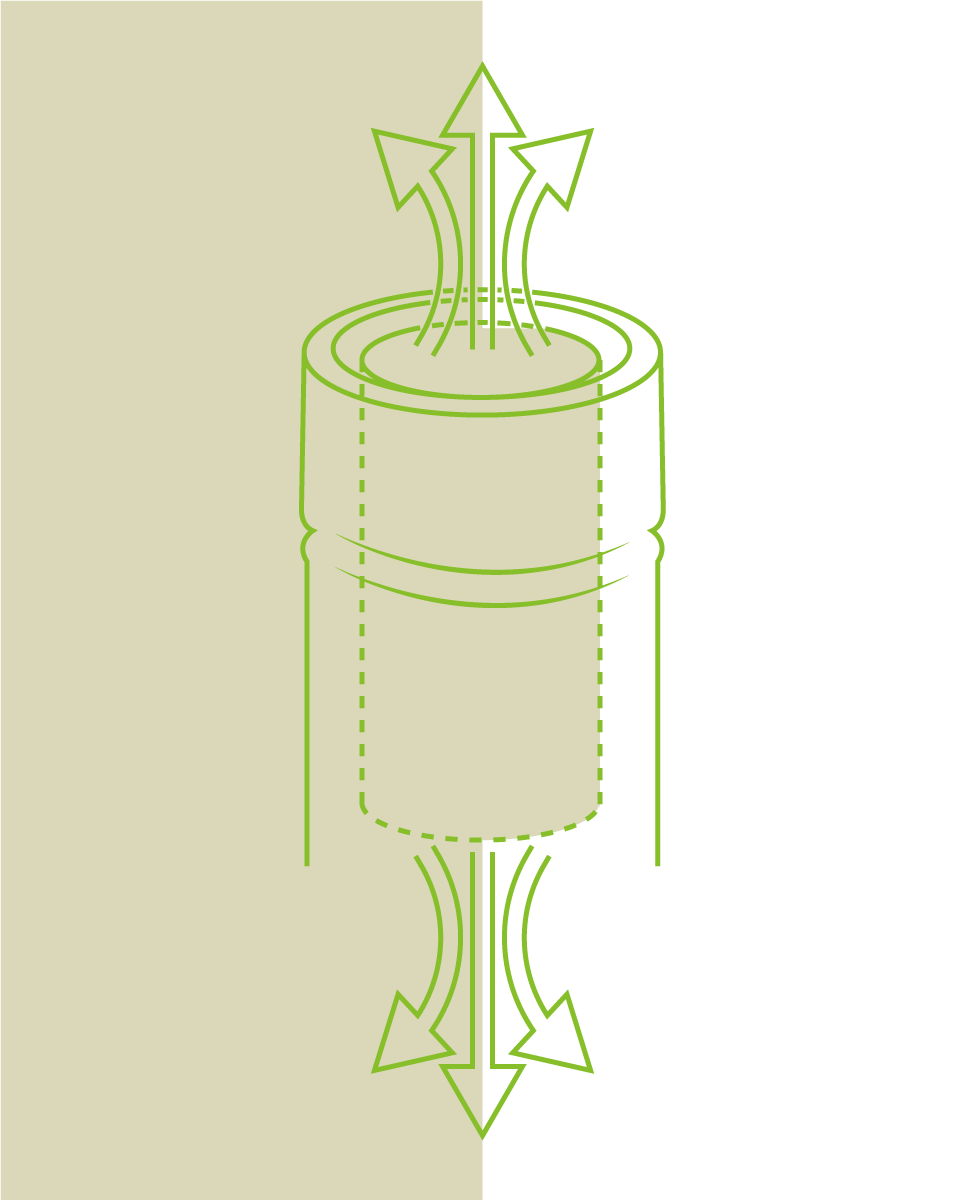

Trichloroanisole (TCA) contamination is a concern throughout the entire cork production process, from the forest stage to the final cork stopper. Early detection of TCA during production is critical, as isolating it early minimizes its impact on the final product. Implementing a smart TCA sensor enables real-time monitoring and rapid intervention, ensuring that TCA contamination is detected and addressed promptly, ultimately improving the quality and reliability of cork products.

To monitor this critical parameter, we have developed a Smart Sensor, a contribution to Cork Supply's Digital Transformation initiative. This advanced process control unit is suitable to be integrated into a comprehensive end-to-end (E2E) platform designed to capture data from the sensor, process it efficiently, and disseminate actionable information. This system enhances traceability and enables data-driven decision-making, ensuring superior quality control throughout the cork production process.

The Smart Sensor's deep learning / AI capabilities eliminate the need for trained personnel to capture and process data manually, making it highly reliable and compatible with industrial environments. This innovation is a contribution to ensure consistent monitoring and quality control minimizing human intervention.

In this study, we present the results gathered using our new system, from the forest to the final cork stopper. Our aim is to demonstrate the performance of the Smart TCA Sensor in monitoring and analyzing various cork materials throughout the production process.